Thread whirling: Achieving sharp crests!

Thread whirling is Schwanog‘s prime discipline when it comes to maximum precision and quality in the manufacturing of bone screws.

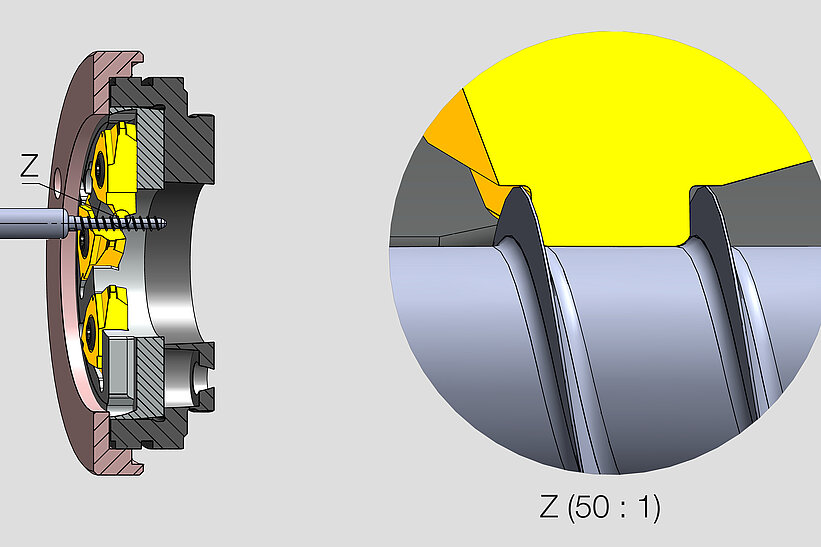

Especially with bone screws, the thread often requires sharp crests in order for the surgeon to apply the screw quicker and more securely.

Until now, the size of the grinding wheel radius determined the size of the crest radii which meant radii smaller R0.04mm (.0016”) could not be achieved economically.

Schwanog found a way to grind a majority of thread profiles with sharp crests. However, this must be verified for each individual case and in advance by our design department.

Make use of Schwanog‘s know-how for your whirling applications. Whether you require standard or exceptional challenges – we are here to help you!