Show details

Show details

Our manufacturing facilities

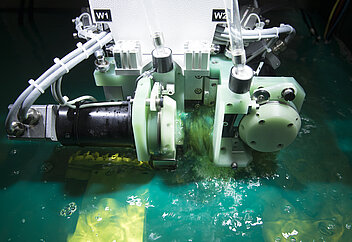

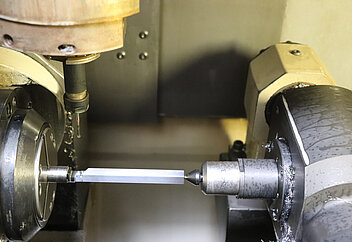

Grinding, EDM and milling are the three main processes we use to manufacture with the highest precision. Standard and special holders are machined in the milling center, while the contour of the exchangeable inserts is either eroded or ground. As both exchangeable inserts and holders are manufactured in-house, core processes come from a single source which means that we can respond quickly and flexibly to customer requirements. Continuous investment in our production facilities and the process optimization that goes hand in hand with it make it possible for us to work at the highest technological level through the use of robots. For us as a manufacturer of grooving tools, process efficiency is crucial as it ensures short lead times in the manufacturing of individual tools.