Efficient broaching of internal hexagons!

One of the classic applications in the medical industry is the machining of screw heads on implants. Most orthopedic implants have an internal hex.

Machining this to optimum levels of efficiency is a typical task for Schwanog. Worldwide applications and quantities in the medical industry are rising continuously and every second of machining time counts.

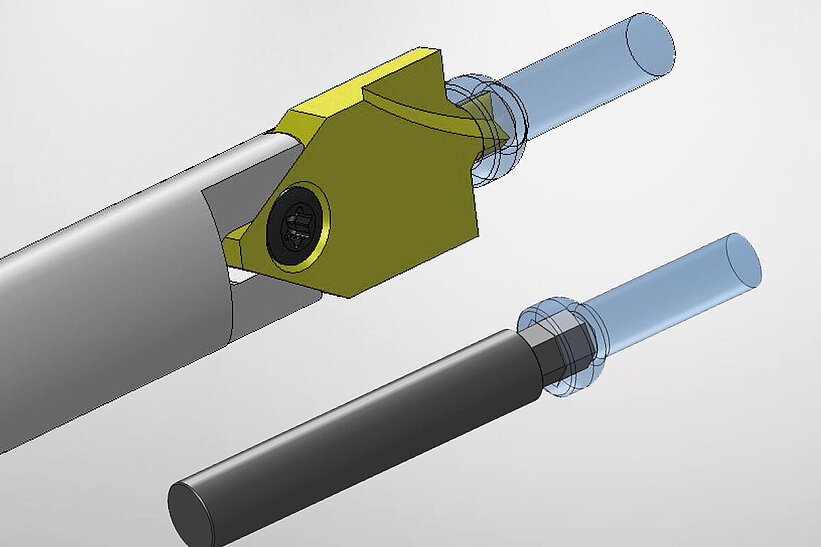

Schwanog demonstrates a valuable way to save on tool costs while using insertable form drills as well as internal hex broaching tools.

First, the core hole is drilled using the PWP insertable form drill. Then the broach is utilized to establish the internal hex form with a single pass. Thus, creating the edges of the hex within a remarkably short period of time.

As a result, part costs can be reduced by as much as 40%.

Benefits:

- Highly efficient machining of bone screws

- Part cost reduction of up to 40%

- Increase in productivity due to addition of PWP form drill and ID hex broaching tool