Grooves with PWP system or full-HM/full-HSS

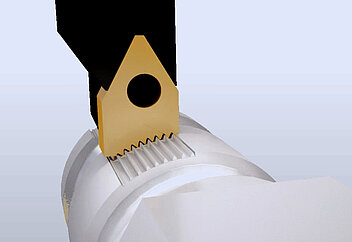

The tried and tested PWP system as well as full-HM and full-HSS tools are also used for groove cutting.

Keyways can be cut in smaller bores from Ø 11 using exchangeable inserts. The advantage of the PWP system compared to a full-HM or full-HSS tool is the significantly lower price. The quick-change capability of the inserts and a high changeover precision mean that machining can usually be continued immediately after the tool change, without the need for readjustment

Gears in the diameter range 12 mm can be manufactured with the Schwanog/VHM internal shaping tools. Finish machining is possible directly on a machine with C-axis. VHM is suitable for soft materials such as non-ferrous metals or free-cutting steel. HSS is used for materials that are more difficult to machine or for any materials at low cutting speeds.

Show details

Show details