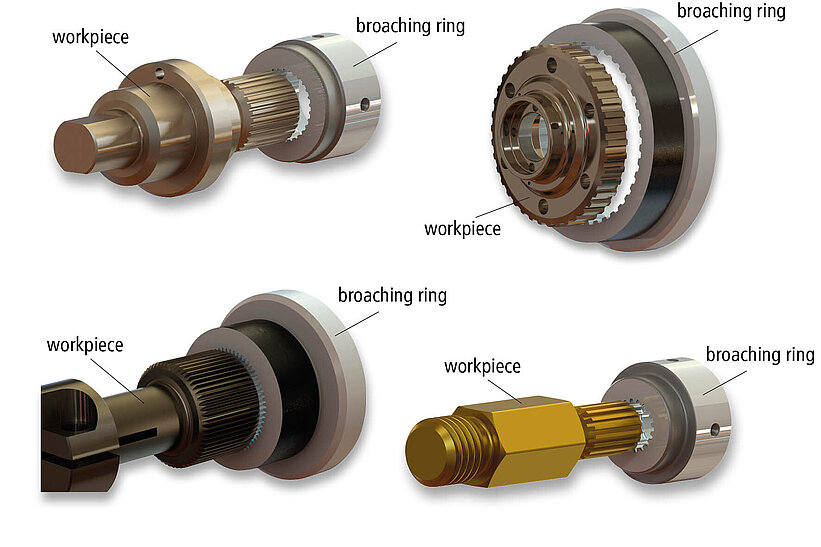

Efficient broaching of splines with Schwanog broaching rings

The use of Schwanog broaching rings as a serration tool offers great advantages and allows splines to be produced quicker. The splines are completely produced in one stroke at a rate that is much faster than conventional milling operations.

Another advantage over milling is that the broaching rings can get close to a collar, which is technically not possible with milling due to the diameter of the milling cutter. An undercut at the end of the spline is beneficial for chip removal and the decreasing cutting speed.

Depending on the application, a fixed or rotary broaching holder (wobble or floating holder), is required. Schwanog broaching holders are designed in such a way that a broaching machine is often not required, achieving the complete machining of parts on a lathe. The 1° inclined design of the wobble / broaching holder reduces the contact force by up to 80%. This is achieved by concentrating the contact force on a smaller segment of the profile to be broached.

The advantages:

- Significant cost reduction using broaching rings

- Broaching up to the collar

- Complete machining on the lathe

- Reduction of the contact pressure by up to 80%

- Can be used on most materials

Important for your production planning:

Broaching rings are not suitable when using materials with a tensile strength >1000 N/mm² (145 ksi). There are also limits to the spline depth and machine stability.

Our team will be happy to inform you about possible applications of our broaching rings for your part.