Hydrokomp prefers Schwanog productg solutions!

Hydrokomp, based in Mücke, Hesse, was founded in 1998 and has successfully positioneditself as an equipment partner for the manufacturing of international machines and fixtures for over 20 years.

Hydrokomp is headed by Managing Director Dipl. Ing. (FH) Karl-Heinz Freund and specializes in the design and manufacture of hydraulic components, coupling systems and clamping technology at two locations. The company succession is ensured by two sons who are actively involved in the company. Customer consultation with experienced development engineers, design and inhouse production with very modern machinery are the strengths of the company. As a result, constructive ideas are also turned into customerspecific special solutions for maximum productivity when products outside the catalog are needed. From the individual component to the complete system, each of the products is developed and produced according to the highest quality standards. With around 40 employees, the company is on course for success and has also coped well with the difficult economic conditions of the last two years.

Schwanog as a partner for special tools since 2021.

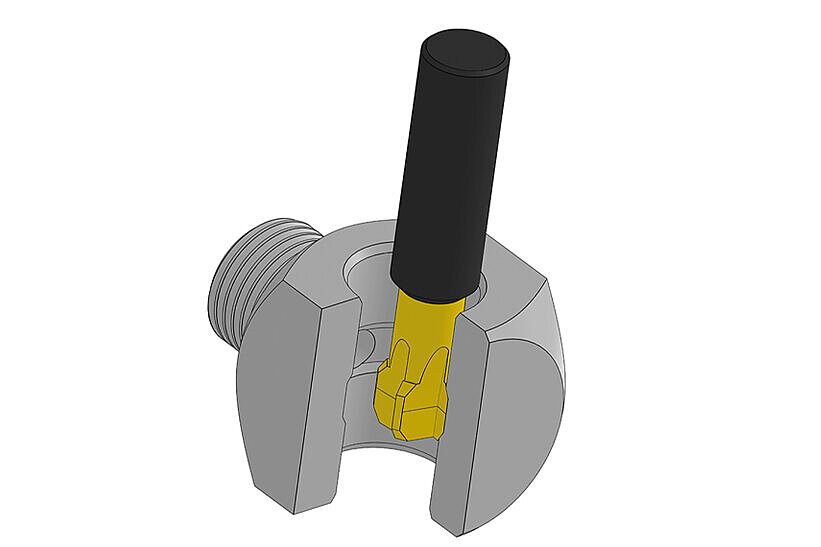

The clear quality philosophy and the demand for maximum productivity brought the two companies together in May 2021. For the machining of complex turned parts on swiss-type and conventional lathes with around 3 million parts per year, Hydrokomp was looking for a supplier who could meet the requirements for unit cost reduction, productivity increase and reduction of production steps. In addition, maximum flexibility was required to offer efficient solutions for the typical small batch sizes of 500 - 5,000 pieces. Schwanog sales representative Jörg Hönle was able to convince the Hydrokomp team, with production manager Michael Hohl, of Schwanog's products and expertise right from the start. As a result, insertable form tools are now supplied for OD grooving, form drilling and form milling applications. The application shown here with the Schwanog form milling cutter is the best example of the solution competence.

Hydrokomp enthusiastic about Schwanog solutions

Michael Hohl is very impressed with Schwanog’s achievements. Although we have only been working together for about a year, the production processes are quite efficient and fast. For Hydrokomp, the main advantages are the simpler production of complex contours and greater flexibility in production. Machining complete contours in one pass leads to significant unit cost reductions and replaces the 2 to 3 standard tools that had been used until then. The Hydrokomp team was also impressed by the process reliability of finished components right off the machine without reworking.

Production manager Michael Hohl is convinced:

Schwanog always delivers a coherent overall concept. Be it the on-site service or the design and manufacture of the tools. The products supplied are also characterized by high dimensional accuracy and tool life. For us, Schwanog is the first point of contact in the area of special solutions."

Both companies have agreed to cooperate even more closely in the future and agree on further potential for unit cost reduction and process optimization.