Milling instead of Broaching with excessively high tensile strength Materials!

Broaching tools have a proven track record extending over many years in the manufacturing of gear splines and grooves. However, if the component material being machined has a very high tensile strength, the broaching process reaches the limits of its capabilities and precision suffers as a result.

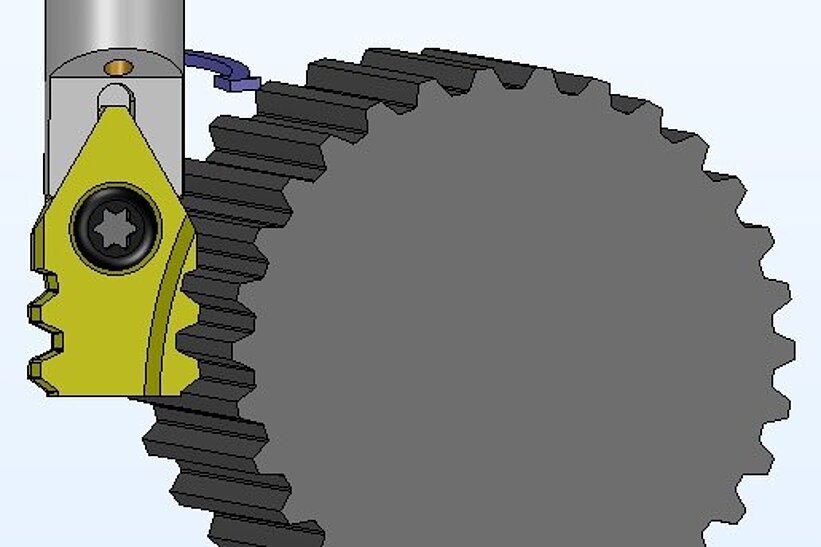

As a highly productive solution to this problem, Schwanog has developed a two-sided insertable tool capable of milling gear splines and grooves to a significant precision level of ±0.01 mm.

As if that were not already sufficient enough, you also stand to benefit from lower tools costs. Schwanog also has the advantage of having a reliable process solution, faster tool changeover times, and lower coating costs.

The PWP insertable tool is a good example of the way in which we boost the productivity of our customers while providing them with a functional solution.

Have we tempted you to take a leap forward in productivity? If so, please e-mail your part drawing to Schwanog with the most important of your requirements, or simply give us a call.

We look forward to hearing from you!