Productive form milling with Schwanog!

Particularly when producing complex profiles and contours on a part, the aim is to exploit all production-related potential for maximum productivity. However, standardized milling operations and tools quickly reach their limits.

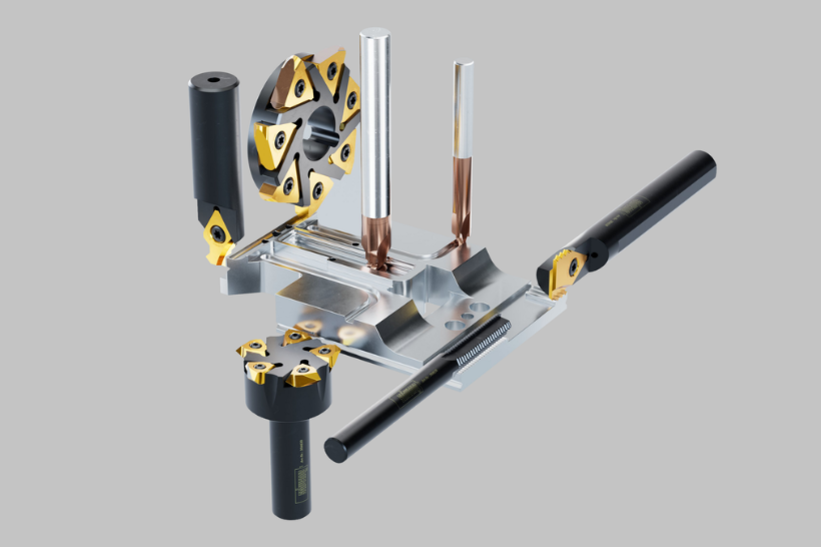

Schwanog also proves in form milling that significant advantages in productivity and precision can be achieved with tooling solutions individually manufactured according to customer drawing. Whether freeform surfaces, specific geometric forms or application-specific contours, individually manufactured Schwanog tooling solutions can optimally meet the special challenges of form milling. These include specific cutting conditions, minimizing vibrations, efficient chip removal or optimized cooling processes.

Benefit from the advantages of Schwanog form tools for your manufacturing processes. Whether milling special forms, grooves or serrations – we have the right solution for you.

Regardless of whether you need solid carbide, two- or multi-edge interchangeable milling inserts, we will select the optimal solution that fits your requirements.