18. November 2022

The Schwanog Selector System

The market for precision parts in the supply chain industry is mainly characterized by medium and large sized batches with the highest demands for quality and zero error tolerance.

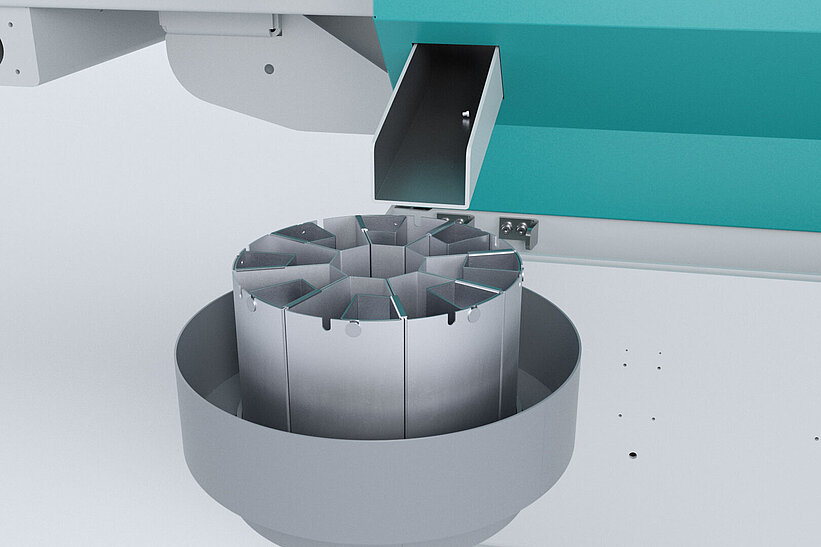

The Schwanog parts selector divides production batches into eight smaller units using bins.

Especially in lights-out production lines or production lines with limited personnel, sorting costs can be significantly reduced in case of tool breakage or other disruptive factors.

Function

- Partition of production batches into smaller units using selector bins

- Bin system with indexing table which are passed through the part chute of the production unit

- Time or quantity-dependent indexing to respectively one bin

Inspection

- Visual check / inspection of the produced parts in the last selector bin

- If these parts are in flawless condition, all other parts in the already filled bins are true to size as well.

- If these parts are faulty, you will exam the parts in the filled bins in reverse order until you find flawless parts.

- This reduces the sorting to a single bin.

- Normally this is a fraction of the production batch which is usually channeled into a part container.

Oil-filled, double bins

- For jolts and scratch sensitive parts the use of over floating, oil-filled double bins offers a qualitative, safe solution.

- Manufactured parts falling into the oil-filled bin, oil with its dampening effect due to its density, prevents quality-reducing jolts and scratches.

Increase your productivity: With the Schwanog Selector system!

Applications

- Single-spindle lathes

- Multi-spindle automatic lathes

- Swiss-type lathes

- Rotary transfer machines

- Punch and stamping machines

- Gear cutting machines

- Spring coiling machines

- and many more upon request

The Schwanog Selector System

Share: